| ||

| Metropower Portal | ||

| ||

GUIDE: - K Series 4 x 100 Hub Conversion GUIDE: - K Series 4 x 100 Hub ConversionModerators: Jump to page : 1 Now viewing page 1 [25 messages per page] | |

| Technical Area-> Technical | Message format |

| Conor_GTa |

| ||

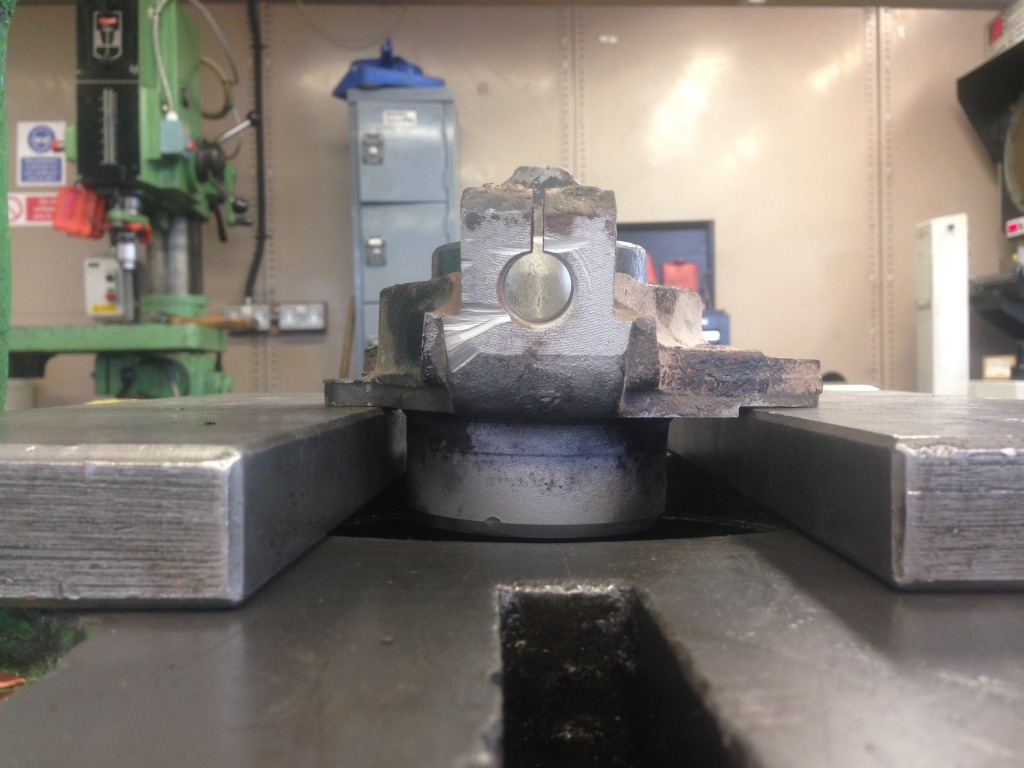

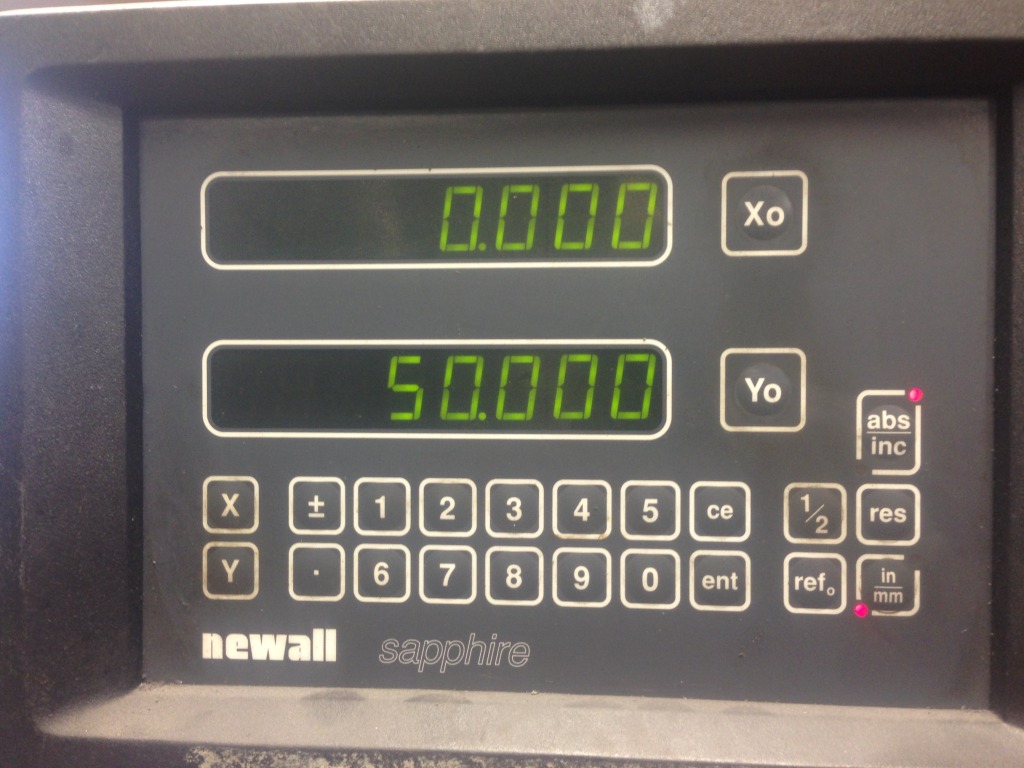

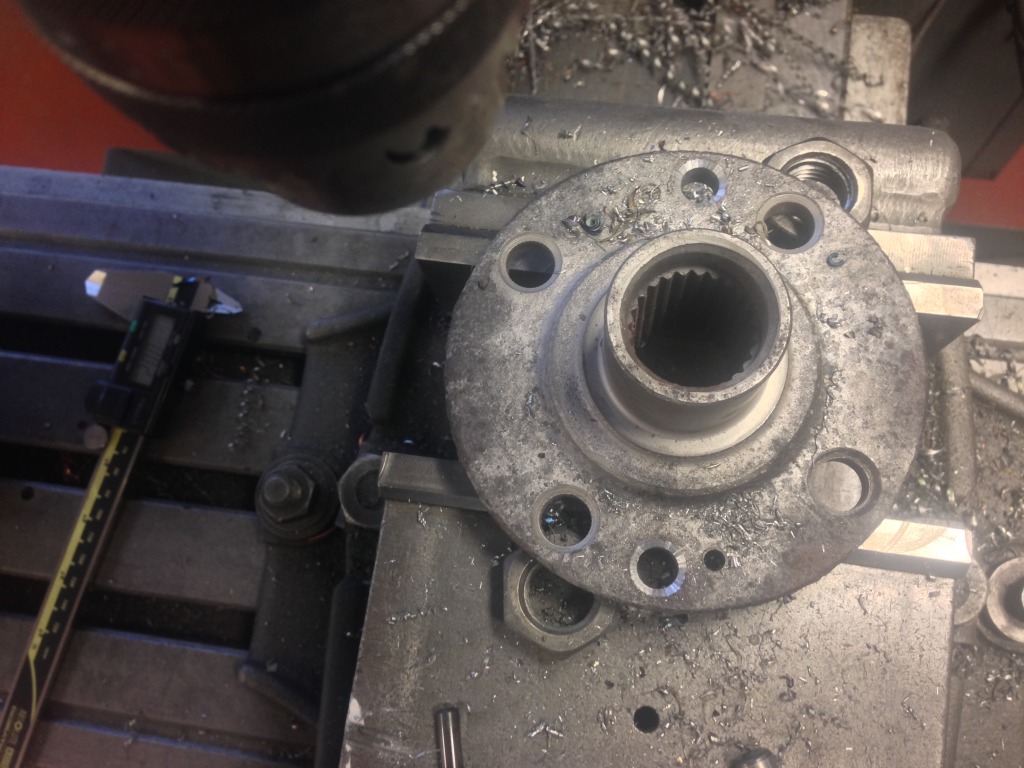

| Veteran Posts: 422     Location: Herne Bay Kent | Had quite a few people ask me how I done this so thought I would make a guide to help people out. Step by step of what I done and what you need What you need : Complete metro k series front hubs Classic mini or A series metro rear hubs Brand new front wheel bearing kitBrand new rear wheel bearing kit(Optional) Brand new top ball joint 3/8 studs ( length depends on choice of wheels, spacers etc. I went with 50mm) Strip down the hubs of bearings studs  Insert the clip into the front of the hub casing  You will need access to a bearing press or fly press, insure the hub casing is on a flat surface face down with the bearing to be pressed in from the rear like so   Make sure what your using sits around the outside ring of the bearing  Be sure that the inside of the casing where the bearing will sit is clean free of any dirt or anything that will cause a issue when putting the bearings in.Press the bearing slowly into the hub casing making sure it stays flat until it is at least half way in. Continue to press until it is up against the clip and the front. Once in then you should be able to insert the clip for the rear.Now for the drilling. What you need : 5mm drill piece 10mm drill piece Counter sink drill piece Access to a digital mill will make this much easier as this need to be very precise. The new holes need to be drilled Inbetween the existing stud holes and the brake disc screws  Make sure the hub is secure and flat before drilling anything  You will need to find the centre of the hub   Once found you need to go out 50mm from the centre of the hub  Using the 5mm drill piece, drill the first hole.  Change to the 10mm once the hole is drilled.  I found this made it much faster and easier doing it in two stages. Now drilled to a 10mm hole counter sink the hole  Do each hole on by one as you will be In the right position and again I found this much easier as I managed to lock the mill at 50mm Now from where you are go back to the centre of the hub and go 50mm in the opposite direction of the hole you just drilled. Drill the second hole in the same way and it should now look something like this  Once the second hole is drilled go back to the centre then continue with the 3rd and 4th hole. Once done it should look like this  Now for pressing the studs in I tapped them in slightly with a hammer just to hold them in place  Pressing them is pretty easy and straight forward, same as the bearings make sure it's flat and that you are covering the back of the stud  Continue pressing until the basically won't go anymore. I forgot to get pictures for the next bit I do apologise Pressing the hub flange into the bearing. I done this using the old bearing case and socket with the hub facing down on a flat surface. This just stops the inside of the bearing coming out when pressing the flange in and doing it upside down I managed to keep a eye on the bearing. Many people know how to press bearings in but thought I would explain it aswell. The discs will need to be drilled in the same way as the hubs but without counter sink. Centre of the disc and go out 50mm from the centre It should look like this once done  So hopefully this will help a few people out for those who are Intrested in doing it. If you are planning on running wide wheels with a low offset DO NOT run standard lower ball joints. Change to MGF, when I first done the conversion I didn't and kept popping ball joints out and all I can say is that it'a not fun when it happens and scares the hell out of you! Lucky I was only going 15mph and local when this happened to me. I chose to run 50mm studs as I will be using mini lights from time to time and the do not clear MPI brakes with out a spacer. So I would suggest around a 40mm studs. Insure that that the blank on the stud does not come out of the disc to much as this will cause issues when bolting the wheel on and the shell but could bottom out on the blank. Think that's all. Any question just comment on here as I may have missed something and you could point something out that might help someone's else out. Thanks for reading Conor | ||

| Conor_GTa |

| ||

| Veteran Posts: 422     Location: Herne Bay Kent | I'll will add photos for the rears on Monday once they get put back on. They are a straight bolt on job and bearings are the same but i will add pictures and a write up | ||

| Morey |

| ||

Events Organiser MP Admin Posts: 1923       Location: Somerset | Fantastic work Connor, stickied for now. Hopefully put up on the portal soon. | ||

| Conor_GTa |

| ||

| Veteran Posts: 422     Location: Herne Bay Kent | Cheers George I'll be posting more into this about the rears later tonight when I finish work | ||

| Conor_GTa |

| ||

| Veteran Posts: 422     Location: Herne Bay Kent | Rear hubs You will need a series metro or mini The rears are a straight bolt on The bearings are the same as k series so no issues there With choice of rear drums there are the standard size ones  The standard drums will set near flush with the arch with minilites wheels (7j ET-7) With these I would suggest approx 35mm studs  The other option is the drum with a built in 25mm spacer With thes you will need 60mm studs  This is a photo of 60mm studs  And a photo of how wide it will be with the built in 25mm spacer  For wheel nuts I've used these they are identical to standard metro ones and have found these are the best  A few people have said why 4x100 on the front and 4 x 101.6 on the rear. I have never had issues of running it this way and this conversion is simply for more wheel choice Any a question feel free to ask Thanks Conor | ||

| Frijz |

| ||

New user Posts: 23 Location: Moorland, Somerset | Just in the process of doing this as I have spare time in the machine shop at college, how have you gone about securing the disc as the screw hole doesnt line up. And are your wheel different PCD's or have you used some adaptor or something? | ||

| Conor_GTa |

| ||

| Veteran Posts: 422     Location: Herne Bay Kent | Frijz - 5/3/2015 1:40 PM Just in the process of doing this as I have spare time in the machine shop at college, how have you gone about securing the disc as the screw hole doesnt line up. And are your wheel different PCD's or have you used some adaptor or something? Disc can be drilled so they line up mate just mine didn't. Not using any adaptors either the only reason I won't go to 4x4" is the fact that if you look at the distance from the edge of the hub to the orginal holes and then the distance to the new they are the same so I didn't wanna go out any further. It can probably be done but going out 50mm from the centre was easier at the time as I will be running 4x4" wheels and 4x100 wheels | ||

| Paul r |

| ||

| Extreme Veteran Posts: 539   Location: Swindon, Wilts | another one to add for anyone carrying out the rear conversion is the fact you can use mini fin drums, these are a lot lighter than the cast alternatives. I personally am using mini fins due to wanting to shed as much weight as possible and doing the conversion to use 10" wheels as in total i am saving nearly 10kg over my old 14" wheels and cast drums. the front is staying 95.25 though as im using GTA 6 spokes which are the lightest wheel that i could get cheap saving 5kg on the front over 14" kn vectors. | ||

| t3gav |

| ||

| Elite Veteran Posts: 664     Location: Herts | How come they pop balljoints? | ||

| Paul r |

| ||

| Extreme Veteran Posts: 539   Location: Swindon, Wilts | only reason it will pop joints is being to low for the ball joint like classic minis do if you go to low. mgf ones are at a slightly different angle hence lasting longer and adding more negative camber fuck all to do with the hub conversion | ||

| Jump to page : 1 Now viewing page 1 [25 messages per page] |

| Printer friendly version E-mail a link to this thread Jump to forum : |

| (Delete all cookies set by this site) | |

| Running MegaBBS ASP Forum Software v2.0 © 2003 PD9 Software | |